So, per the DoE's EIA, we just need to install enough additional solar panels to generate 956 GW of energy - roughly $3T (including the land).

The North American Electric Reliability Corporation (NERC), the electric reliability organization certified by the Federal Energy Regulatory Commission to establish and enforce reliability standards for three major electrical interconnections serving the United States, issues a reliability assessment each year. NERC estimated in November 2012 that the United States would have 966 gigawatts (GW) of electric supply capacity available for the summer of 2013. NERC estimated that about 786 GW would be needed to meet projected peak electricity demand and determined that another 117 GW should be available in case of supply outages or extreme weather (known as target reserve supply).

The United States has 63 GW of capacity above and beyond the NERC target reserve supply. The level of above-target capacity varies by region: some areas have significant excess capacity and others are more constrained. ERCOT, the region that makes up most of Texas is of particular concern and is projected to be below target capacity for the summer of 2013 forward. Because of the layout of the electric transmission grid, excess resources in one region cannot necessarily be used to make up for a deficit in another region (ERCOT is particularly limited when it comes to importing electricity).

The electricity industry has reserve capacity on hand to maintain reliability. Because large-scale electricity storage is not currently economic, electric systems must have sufficient supply resources available to meet electricity demand and replace unexpected losses of supply. Each NERC region has a reserve margin target—the amount of supply capacity over and above a region's expected hourly peak demand for the year needed for reliability. The NERC regions' reserve margin targets typically range from 14%-17% and together total 117 GW of supply capacity.

]]>"Hyperion, a manufacturing system developed by Twin Creeks Technologies, solves the problem of thick wafers with a technique called Proton Induced Exfoliation (PIE). In PIE, high-energy protons (or hydrogen ions) are embedded into “donor” wafers — standard wafers of silicon, germanium or other single-crystal materials— where they form a uniform layer beneath the surface of the donor. The physical attributes of hydrogen, combined with the conditions created by Hyperion, permit the ions to penetrate the surface of the donor wafer without changing its inherent properties and characteristics."

Financed at about $100M, this firm may radically alter the course of human history to bring solar PV to grid parity within a few years.

"A single Hyperion 3 system, our commercial-scale manufacturing tool, can process over 1.5 million thin wafers per year, enough for more than 6 megawatts worth of solar cells. While Twin Creeks will initially concentrate on silicon wafers, Hyperion can be employed to produce thin crystalline wafers made from gallium arsenide, germanium, and other materials.

They announced today they have complete manufacturing systems ready to ship and install. They go on with their explanation of their approach...

"Solar cells, LEDs, and the chips inside everything from automobiles and computers to greeting cards come from expensive monocrystalline wafers made from materials like silicon, germanium, silicon carbide or gallium nitride. Despite tremendous technological advances over the last several decades, wafers still contain more material than manufacturers need.

A state-of-the-art silicon wafer today might measure 200 microns, or 200 millionths of a meter, thick. While incredibly thin, 90 percent of the material like silicon primarily serves to give the wafer structure. Only a thin surface layer of the wafer ultimately gets used for active functions like transmitting signals."

"The additional heft adds cost. Silicon, for instance, is still the most expensive component of a finished solar module and the single highest expense when it comes to generating solar power. Worldwide fluctuations in supply and demand can also upset sales forecasts and manufacturing strategies. A long-term supply contract for silicon that gives a company a competitive advantage one year can become a liability the next.

Twin Creeks was founded on a desire to disruptively reduce the cost of solar energy to achieve grid parity. With the completion of our latest-generation Hyperion 3 toolset, we have a production system that can produce ultra-thin wafers less than one-tenth the thickness of conventional silicon solar wafers. Hyperion can fundamentally change the cost structure of many other industries that rely on high-cost, single-crystal wafers for their devices.

Today, solar is our development platform to invent and scale the technology and processes needed to make Hyperion the industry standard for low-cost, high-value single crystal substrate production."

It will be interesting to watch the roll-out of this technology and if it will directly effect the world economy as their claims suggest. For more information about Twin Creeks Technologies and their credentials...

]]>New Hampshire, USA -- The "Oracle of Omaha," who made his fortune by betting on technologies that appear underpriced, is now putting his money into solar.

The solar industry got a turbo-boost of both name recognition and mainstream credibility on Wednesday as a subsidiary of billionaire Warren Buffett’s investment company MidAmerican Energy Holdings announced plans to purchase the Topaz Solar power development from thin-film PV module maker First Solar. Terms of the deal were not disclosed.

The 550-megawatt Topaz project in San Luis Obispo County, Calif., is among the world’s biggest solar farms under development, and many times larger than any project currently in operation. The First Solar project was not able to close its conditional loan guarantee with the Department of Energy prior to the Sept. 30 deadline, but it has gone ahead anyway. Construction on the project began in November and is expected to run through 2015. According to First Solar, it will create about 400 construction jobs.

The $2 billion project will include First Solar’s thin-film panels, and the company will build, operate and maintain the project for MidAmerican. Pacific Gas and Electric will buy the electricity under a 25-year power purchase agreement.

Based in Iowa, MidAmerican, a subsidiary of Buffett’s Berkshire Hathaway, is already a big player in wind energy. Some analysts are saying that the company's move into solar power could be linked to the expiring Production Tax Credit for wind power, which is set to go away at the end of 2012. The solar industry, which is hoping for an extension of the Treasury Department grant that expires at the end of this year, still has an Investment Tax Credit that runs through 2016. That could make solar a safer bet.

Regardless of the reason, MidAmerican clearly sees the Topaz project as a financial opportunity even without federal backing. SolarCity recently took a similar route when it announced that Bank of America Merrill Lynch was helping it move ahead with its $1 billion Solar Strong project, which also failed to close on a loan guarantee from the DOE.

The project “demonstrates that solar energy is a commercially viable technology without the support of governmental loan guarantees and reflects the type of solar and other renewable generation that MidAmerican will continue to seek to add to its unregulated portfolio," said Greg Abel, chairman, president and CEO of MidAmerican Energy Holdings Company in a press release.

“We have done a lot of work over the last several years to integrate sustainable practices into our everyday business operations,” said Rodney McMullen, president and chief operating officer of Kroger. “Today, we are proud to unveil Kroger’s first operational solar energy project. Smith’s has done a tremendous job bringing this to realization. Kroger will continue reducing energy consumption and testing technologies that support future use of alternative energy sources.”

The Smith’s stores were selected due to the sunny climate and economic incentives offered by energy provider PNM. Affordable Solar, based in Albuquerque, designed and installed the panels. Kroger is also developing photovoltaic systems in stores located in Wilsonville, Oregon (Fred Meyer) and Cincinnati, Ohio (Kroger).

]]>The California Public Utilities Commission has authorized the use of tradable renewable-energy credits as an incentive for increased adoption of rooftop solar photovoltaic electricity.

Renewable-energy credits are certificates that represent the value of a specific amount of renewable electricity that has been generated, and are typically amassed in units that represent 1 megawatt-hour of electricity, equivalent to 1,000 kilowatt-hours.

Electric utilities purchase such credits to help meet requirements that they produce a certain percentage of electricity from renewable sources. The commission's decision allows RECs to be bought and sold "unbundled," meaning the solar owner gets the electricity, but can sell the certificate that represents its environmental attributes.

In New Jersey and other states, such certificates have been traded on the market for hundreds of dollars per unit and have produced significant revenues for owners of small solar arrays. Prices for Solar Renewable Energy Certificates in the Garden State have at times exceeded $600 for 1 megawatt-hour of production. The money generated helps to offset the cost of solar equipment.

The California program will be much more modest initially than New Jersey's, with a $50 interim price cap for certificates or credits bought by the state's three large investor-owned utilities to meet their renewable-purchase requirements. The price cap will be in place through 2011. The decision says the temporary cap does not mean that $50 should be regarded as a "reasonable price" for RECs. Other companies or organizations that may buy RECs would not be subject to the cap.

An average residential solar-electric system with a capacity of 5 kilowatts in much of California might be expected to generate about 7,000 kilowatt-hours a year, potentially worth about seven credits under the tradable REC mechanism.

At $50 each, their sale could amount to $350 annually for an average system. That would be much less than New Jersey solar owners typically receive, but at present California homeowners and small-business owners get nothing for RECs. Over the decades-long life of a PV system, such an amount could cover much of a small array's cost.

One drawback of renewable-energy credits is that they add another layer of complexity for mom-and-pop consumers seeking to determine whether solar electricity is right for them. In a news release, the CPUC did not say when REC trading would begin, and did not specifically say that homeowners and small-business owners would be eligible.

However, the commission's written decision says that owners of distributed generation installations, such as solar PV systems, would own the RECs associated with their energy production, "and can therefore sell them, regardless of whether the DG owners participate in net metering."

Another part of the decision notes that to participate in the market, owners would have to file with and meet requirements of an organization called the Western Renewable Energy Generation Information System. That system excludes solar PV arrays under 1 kilowatt of production capacity, meaning "some owners of very small DG systems may not be able to participate," the decision says.

The utilities commission's news release said that "the ability to sell RECs associated with distributed generation will provide incentives for greater rooftop solar and other distributed generation."

Michael R. Peevey, the commission's president, said in the news release: "The essential elements of this framework are intended to support this market well into the future. Although the tradable REC market may be modest in the next two or three years, the market rules put in place in this decision will both allow this new market to develop and provide robust rules as the tradable REC market matures."

]]>Power generation will begin in the second half of 2010 with final completion expected by year end. In the first full year of operation, the system will generate sufficient energy to power 17,150 homes and avoid 41,000 tons of CO2 – the equivalent of removing 8,000 cars from the road.

SunEdison will jointly develop the project with financing partner Banco Santander. Additional financial partners are expected to join the project for final ownership.

“SunEdison is focused on enabling the growth of global solar markets through strong capabilities in project finance, engineering, low-cost procurement and operations and maintenance services,” commented Carlos Domenech, President of SunEdison.

“Veneto is taking decisive action to advance the use of clean, renewable energy sources,” said Renzo Marangon, government official of the Veneto region. “At the same time, this project is expected to create over 350 local construction jobs and build expertise in advanced energy technologies. We expect Rovigo to serve as a European model for large-scale, alternative-energy projects.”

“A critical element of our approach is working closely with the right partners,” added Pancho Perez, General Manager for Europe and MENA region at SunEdison, “including developers, suppliers and contractors. For the Rovigo project, we selected Isolux Corsán, a large-scale infrastructure construction company with a strong track record in utility-scale solar plants.”

“We are pleased to be selected by SunEdison to construct the largest PV solar plant in Europe. We are looking forward to extending this partnership beyond Italy,” said Luis Delso, President of Isolux Corsán.

At 72 megawatts, this solar-power plant will be the largest in Europe. Currently, the largest facility is a 60MW solar farm in Olmedilla, Spain, followed by a 50 MW in Strasskirchen, Germany, built by MEMC through a joint venture agreement.

About SunEdison

SunEdison is a global provider of solar-energy services. The company finances, installs and operates distributed power plants using proven photovoltaic technologies, delivering fully managed, predictably priced solar energy services for its commercial, government and utility customers. In 2009, SunEdison delivered more kilowatt hours (kWh) of energy than any other solar services provider in North America. For more information about SunEdison, please visit www.sunedison.com

About MEMC

MEMC is a global leader in the manufacture and sale of wafers and related intermediate products to the semiconductor and solar industries. MEMC has been a pioneer in the design and development of silicon wafer technologies for 50 years. With R&D and manufacturing facilities in the U.S., Europe, and Asia, MEMC enables the next generation of high-performance semiconductor devices and solar cells. Through its SunEdison division, MEMC is also a developer of solar power projects and North America's largest solar energy services provider.

MEMC’s common stock is listed on the New York Stock Exchange under the symbol “WFR” and is included in the S&P 500 Index. For more information about MEMC, please visit www.memc.com.

About Isolux Corsán

Isolux Corsán is the largest unlisted Spanish construction company and the seventh largest in the entire construction industry in Spain (listed and unlisted). Increasingly focused on international markets, it currently operates in 34 countries. Its main growth drivers are energy transport, toll road and car-park concessions world-wide, and the construction of environmentally friendly infrastructures. At present, the Isolux Corsán group leads the market in high-voltage energy transport concessions, with 9,285 km of power cables. It has more than 1,400 km of toll roads in Brazil, India, Mexico and Spain and over 20,000 parking spaces under concession. In the photovoltaic sector, Isolux Corsán is one of the biggest installers world-wide, with more than 178 MW executed or in progress in Spain and Italy, and an additional 72 MW about to be built in Rovigo (Italy). It also has experience in building and maintaining renewable-energy infrastructures (wind-farms, PV power plants and PV module and biodiesel factories). All this and its investments in companies within the renewables industry enable it to successfully pursue a strategy of diversification in international markets and in products and services. In 2008, the company reported over €3.2 bn in revenues, with an EBITDA of €205 mill and a portfolio of €15.5 bn for the next years. For further information, visit www.isoluxcorsan.com

About Banco Santander

Banco Santander (SAN.MC, STD.N, BNC.LN) is a retail and commercial bank, based in Spain, with presence in 10 main markets. At the end of 2009, Santander was the largest bank in the euro zone by market capitalization and third in the world by profit. Founded in 1857, Santander had EUR 1,245 billion in managed funds at the end of 2009. Following the acquisition of Sovereign Bancorp. of the U.S. in January 2009, Santander has 90 million customers, 13,660 branches – more than any other international bank – and 170,000 employees. It is the largest financial group in Spain and Latin America, with leading positions in the United Kingdom and Portugal and a broad presence in Europe through its Santander Consumer Finance arm. In 2009, Santander registered €8,943 million in net attributable profit.

Forward-Looking Statements

Certain matters discussed in this news release are forward-looking statements, including that power generation for the project will begin in the second half of 2010, with final completion of the project expected by the end of 2010. Such statements involve certain risks and uncertainties that could cause actual results to differ materially from those in the forward-looking statements. Potential risks and uncertainties include delays or interruptions in construction of the power plant, including interruptions due to weather or delays in the delivery of transformers, modules or other components; delays due to challenges against the permits or authorizations for the power plant by governmental or third parties; delays in interconnection of the power plant to the electricity grid; changes in the applicable regulatory system, including any incentives for production of electricity for solar power plants; and other risks described in MEMC’s filings with the Securities and Exchange Commission. These forward-looking statements represent MEMC’s and SunEdison’s judgment as of the date of this release. MEMC and SunEdison disclaim, however, any intent or obligation to update these forward-looking statements.

SunEdison

Brad Oswald

Marketing Manager

443-909-7200

or

MEMC Electronic Materials, Inc.

Bill Michalek

Director, IR & Corporate Communications

636-474-5443

Solar Distinction Inc., part of the Noribachi Group said this week that it plans to build a solar photovoltaic manufacturing plant in Albuquerque. The plant will employ 300 within two to three years with a potential of up to 500.

Solar Distinction will also sell its photovoltaic technologies to third party companies throughout the Southwestern U.S.

The plant is set to open by year-end 2010, with enough operating capacity to produce 25 megawatts of solar panels. It will expand to a 50 megawatt capacity within two years, the Noribachi said.

Visible Light Solar Technologies plans to be the first to purchase Solar Distinction solar panel products. Visible Light Solar will be using the panels produced by Solar Distinction as part of its LED lighting fixtures (new or retrofit) with on-and-off-grid energy optimization solutions.

“We are pleased to participate in today’s announcement as one of Solar Distinctions first New Mexico customers,” said J. Dee Dennis, Jr. CEO of Visible Light Solar. “Our order is already in for custom solar panels. Keeping our own carbon footprint low is a big part of our company mission. Once their plant is up and running and our order fulfilled, we will be sourcing local components, supporting the New Mexico economy, reducing shipping costs, and helping revitalize a U.S. manufacturing economy. This is all part of our triple bottom line approach to business.”

Solar Distinction will also sell its photovoltaic technologies to third party companies throughout the Southwestern U.S. Visible Light Solar just announced its expansion into a 32,000 sq-ft facility in Albuquerque and nine new distributors to assist its global outreach.

Moser Baer, an Indian company with aggressive plans to build solar panels and develop power plants, will begin mass production of thin-film panels this month.

The New Delhi company will make the amorphous thin-film panels from its 40-megawatt manufacturing plant in Greater Noida, said Moser Baer executive vice president and CTO Rajiv Arya, who spoke on a panel at the Thin-Film Solar Summit in San Francisco Tuesday.

The company already has lined up $500 million worth of deals to sell its thin-film panels to European customers, which include Ralos Vertriebs and Colexon Energy, both in Germany (see Moser Baer India Signs $500M in Thin-Film Contracts).

Moser Baer began producing panels in small quantities in July. The panels on average can convert 6 percent of the sunlight that strikes them into electricity, Arya said.

Thin-film panels are less efficient than those made with crystalline silicon, which dominate the market today and can reach an efficiency of 18 percent. But thin-films can be made cheaper. Amorphous silicon panels also are able to convert low light better than silicon panels, thin-film proponents say. That means thin-film panels can work longer during the day to produce electricity.

"The overall energy you produce is much higher from amorphous silicon. It gets up early and goes to bed late, so it works harder than crystalline silicon modules," Arya said.

Moser Baer, a data storage company that launched a subsidiary Moser Baer Photo Voltaic in 2005, is on a tear to erect manufacturing plants (see Moser Baer to Pump $1.5 Billion into Thin Film).

In Greater Noida, the company is building a 65-megawatt thin-film production facility. It also is constructing a 100-megawatt plant for making crystalline silicon cells, which are assembled into panels at a nearby factory.

The company already has an 80-megawatt crystalline silicon cell manufacturing plant and a panel factory that can produce 80 megawatts worth of panels in Greater Noida.

In the city of Chennai, Moser Baer is building a 500-megawatt thin-film production plant. The plant will be built in three phases, with the first 167-megawatt capacity being completed by December 2009. The rest will be completed by Aug. 2010, Arya said.

Chennai, in the state of Tamil Nadu, is attracting other solar companies thanks to the state government's offer to subsidize the costs of building manufacturing plants. Signet Solar, based in Menlo Park, Calif., plans to build an amorphous silicon production plant there, the company said earlier this year.

Amorphous silicon companies are mostly at the beginning of commercially producing panels. Aside from Moser Baer and Signet, other solar companies also have announced ambitious factory-building plans (see Sharp Guns for U.S. Thin-Film Market and Sanyo Builds New Factory, Enters Thin-Film Fray).

Aside from making solar cells and panels, Moser Baer also plans to build solar power plants to take advantage of India's new feed-in tariff program announced earlier this year.

Feed-in tariffs have played a key role in the worldwide solar energy boom. Solar equipment makers and power plant developers look for such incentives that sometimes draw criticism for supporting an industry at the expense of consumers.

In a typical feed-in tariff program, utilities are required to buy all the electricity generated from renewable sources, such as solar and wind, and pay rates that are higher than the prices for conventional power. The government sets the rates, though utilities can pass on the costs to customers.

Under India's feed-in tariff program, solar power producers will get 15 rupees per kilowatt-hour, or roughly $0.30 per kilowatt hour. Each producer can develop up to 5 megawatts of projects under the program.

The rate will be in effect for the first 50 megawatts worth of projects. The government, which already has gotten 2 gigawatts worth of applications, is working on a second phase of the program that would increase the cap to 1 gigawatt.

Moser Baer plans to develop three projects of 5 megawatts each and use both the crystalline silicon and amorphous silicon panels, Arya said. But the company will start slow and is now building a 1-megawatt system in Punjab.

"India has aggressive plans to open up the market, and it will give us thousands of megawatts in the next three to five years," Arya said.

Pacific Gas & Electric Co. (PG&E) has long invested in renewable energy sources, including geothermal, wind and solar. Earlier this week, the utility company reached for the stars in announcing the first-ever deal of its kind: The California power utility, says spokesperson Jonathan Marshall, plans to purchase clean energy generated by a satellite beaming solar power from orbit.

The agreement between PG&E and Solaren Corp., an eight-year-old company based in Manhattan Beach, Calif., still hinges on state regulatory approval. If the deal gets the green light, Solaren must then privately raise billions of dollars to design, launch and operate a satellite as well as an energy-receiving ground station slated for the Fresno County area, says Cal Boerman, director of energy services for Solaren.

The challenges of building this satellite (due to be completed in 2016) and introducing so-called space-based solar power (SBSP) remain formidable. But driven by the urgency of climate change and the lowering costs of solar technology, a growing number of countries and companies believe an energy revolution could be in the offing.

Why bother harvesting solar energy directly from space? It is abundant, and "you can get [this] power 24/7," says Marty Hoffert, an emeritus professor of physics at New York University. Sunlight is some five to 10 times stronger in space, and its shine would reach energy-gathering satellites placed into geostationary (fixed) orbits—the realm of many currently deployed communications spacecraft—more than 99 percent of the time.

SBSP could, according to energy experts, provide constant, pollution-free power—unlike intermittent wind and cloud cover–sensitive ground-based solar, and without the emissions of fossil fuels or radioactive waste from nuclear power. "[SBSP] is a disruptive technology [in that] it could change the whole energy equation," says Frederick Best, director of the Center for Space Power (CSP) at Texas A&M University in College Station, Tex.

The premise (and promise) of SBSP has been considered scientifically feasible since the late 1960s. The basic concept of beaming microwave frequencies to Earth from orbit has already been proved: A fleet of solar-powered communication satellites routinely beam various electromagnetic frequencies to ground receivers, linking cell phone calls or relaying TV signals to rooftop dishes, for example. Converting solar energy beamed from space into electricity in a power grid, however, has not yet been demonstrated.

Space Energy, a Switzerland-based SBSP start-up, aims to change that by deploying a prototype orbiter in the next several years, possibly before Solaren's pilot plant reaches orbit. "You can argue the physics [of SBSP] all day, but you'll only know with a prototype," says Peter Sage, a co-founder of Space Energy, started in 2008.

Last year, U.S. and Japanese researchers crossed an important SBSP threshold when they wirelessly transmitted microwave energy between two Hawaiian islands about 90 miles (145 kilometers) apart, representing the distance through Earth's atmosphere that a transmission from orbit would have to penetrate, says Frank Little, associate director of the CSP.

By Adam Hadhazy

]]>Suntech's world record breaking multi-crystalline silicon module is powered by Pluto PV cells utilizing solar grade silicon with each PV cell having a conversion efficiency well over 17%. In August, Suntech surpassed the previous record of 15.5% set by Sandia National Labs 15 years ago. The latest record is well above previous records and is a reaffirmation that Suntech's Pluto powered multi-crystalline modules have the highest conversion efficiency in the world.

"We are very pleased to announce that our Pluto technology has been recognized as the most efficient multi-crystalline silicon technology in the world," said Dr. Stuart Wenham, Suntech's Chief Technology Officer. "This shows that it is possible to combine both first class R&D and low cost manufacturing into a commercially viable business model that will bring clean alternative energy to the world's growing energy demands."

Dr. Martin Green, Research Director of the ARC Photovoltaics Centre of Excellence at the University of New South Wales, Australia, and member of the Progress in Photovoltaics Committee said, "The 16.53% conversion efficiency Suntech module has a clear margin over other multi-crystalline silicon photovoltaic technologies. It has set the new benchmark for the highest performance multi-crystalline module."

Suntech brings utility-scale solar to China

Meanwhile, Suntech has announced completion and grid connection of the first 10 MW utility-scale solar power project in China. Located in Shizuishan, Ningxia Autonomous Region, the 10 MW ground mount solar system is the first phase of a 50 MW solar plant that is targeted to be completed by 2011 in conjunction with Suntech's strategic partner, China Energy Conservation Investment Corporation (CECIC). In addition to supplying high quality solar modules for the system, Suntech designed, installed and managed the development of the solar system and holds a minority share of the project.

Dr. Zhengrong Shi, Suntech's Chairman and CEO said, ''Suntech is very pleased and honoured to play a leading role in the development of the first on-grid 10 MW solar PV power plant in China, which represents a major milestone in the development of China's renewable energy industry. With closer cooperation between strategic energy investors, power developers and solution providers, I am confident that solar energy will become increasingly cost effective and achieve grid parity in many locations over the next few years.''

The 10 MW solar system, which was approved by the Ningxia Autonomous Region Development and Reform Commission in June, 2009, is powered by more than 37,000 Suntech solar panels and is projected to displace approximately 20,000 tons of carbon dioxide emissions per year.

Under a strategic agreement announced in 2009, Suntech and CECIC plan to focus on the development of further large scale on-grid solar projects, urban building integrated PV projects, rural off-grid solar projects, and wind-solar hybrid projects.

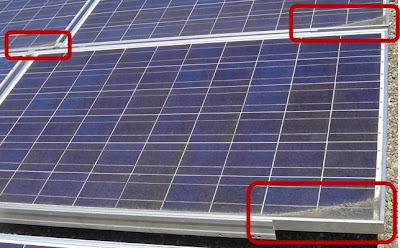

]]>There are two different sets of solar panels on the Google campus — completely flat ones installed on carports, and rooftop ones that are mounted on an angle.

Since the carport solar panels have no tilt, rain does not do a good job of rinsing off the dirt they collect. (Also, the carports are situated across from a sand field, which doesn't help the situation.) After cleaning these panels for the first time after they had been in operation for 15 months, their energy output doubled overnight. Ceaning them again eight months later and their output instantly increased by 36 percent. In fact, Google Staff found that cleaning these panels is the #1 way to maximize the energy they produce. As a result, they have added the carport solar panels to their spring cleaning checklist.

The rooftop solar panels are a different story. The data indicates that rain does a sufficient job of cleaning the tilted solar panels. Some dirt does accumulate in the corners, but the resulting reduction in energy output is fairly small — and cleaning tilted panels does not significantly increase their energy production. So for now, They Mother Nature take care of cleaning the rooftop panels.

If you want to learn more about the solar study, check out these slides showing the effects that seasonality, tilt, dirt, particulate matter, rain and cleaning have on Google's solar energy output.

The announcement follows a competitive bid process opened in March by the U.S. Army’s Senior Energy Council, a body created in October 2008 to accelerate and oversee a sustainable energy strategy aimed at finding alternative energy sources, obtaining increased energy savings and securing energy supplies for U.S. Army installations, personnel, vehicles and other assets.

A federal mandate requires the U.S. Army to reduce its energy consumption by 30 percent by 2015 (compared to 2003) and to cover 25 percent of its energy needs with renewable energies by 2025.

The Fort Irwin project is part of the Army’s “Enhanced Use Leasing” (EUL) program, designed to allow private sector entities “to acquire and leverage value from under-utilized non-excess real estate assets on Army and select Department of Defense Installations.”

The Defense Department’s largest-ever solar energy project

ACCIONA Solar Power and Clark Energy Group’s joint project will develop approximately 500 MW of solar power, a figure that could be increased to 1,000 MW at a later stage. The project will involve concentrating solar power (CSP) and photovoltaic technology and is the U.S. Department of Defense’s largest-ever solar project. To date, the 14 MW solar plant at Nellis Air Force Base, Nevada, and the 2 MW installation at Fort Carson, Colorado, are the Department of Defense’s largest solar power generating plants.

The facilities will be installed at five sites – a total of 21 square miles – following selection for suitability by Army technicians.

The project is at an initial stage and studies are being carried out to identify the most suitable and efficient technological solutions. Construction will take place over a relatively long period of time and will be staggered in several phases: by 2014, the first site development should be sufficiently advanced to cover Fort Irwin’s total energy needs.

“To be selected for this project is an indication of the trust that one of the world’s most technologically advanced organizations places in ACCIONA’s ability to develop renewable projects. It also confirms our position as an active player in the U.S. clean energies market,” said Alberto de Miguel, development director, ACCIONA Energy.

“The Fort Irwin solar power project is an example of how the U.S. Army can lead the nation forward towards a future of energy security,” said Kevin Geiss, energy security program director, U.S. Army.

“Fort Irwin is proud to host this groundbreaking effort by the Department of the Army in partnership with Clark and ACCIONA Solar Power,” said Colonel Jim Chevalier, garrison commander, Fort Irwin. “The plant is the largest solar project in the state and it illustrates the commitment of Fort Irwin and the Army to incorporate environmental stewardship at all levels of operations.”

“Quite frankly, the Department of Defense was a little bit late coming to the topic of efficiency and renewables, but now it’s at the forefront,” said Richard Kidd, a high-ranking official at the U.S. Department of Energy, in a recent statement to The New York Times.

The Nevada Solar One experience

Fort Irwin is located in the Mojave Desert, one of the areas with the most hours of sunlight in the whole of the U.S., making the base an ideal site for solar generating technology. The complex stands midway between Los Angeles and Las Vegas at a location similar to the site of the 64 MW Nevada Solar One concentrating solar power (CSP) facility, installed by ACCIONA Solar Power 82 miles southeast of Las Vegas. Nevada Solar One was grid-connected in June 2007.

In accordance with EUL requirements, the project will be financed and developed by both companies – costs are expected to come to approximately $2 billion – who will deliver services in kind (e.g., operation and maintenance) in exchange for the lease of military land holdings. Any excess electricity produced can be sold to the grid via two high-power transmission lines in the vicinity of Fort Irwin.

The new 500 MW solar facilities are expected to produce approximately 1,000 GWh annually, far exceeding Fort Irwin’s 35 MW peak load. The project will target the sale of generated energy that is not used by the Fort Irwin complex to regional public utilities.

A key market for ACCIONA

The U.S. is a priority market for ACCIONA: the Company operates here with wind power and CSP facilities and is seeking to enhance its presence by taking part in the Obama Administration’s push for renewable energies.

ACCIONA has installed 490 MW of wind power across five wind parks in North Dakota, South Dakota, Illinois and Oklahoma and has projects under development in 15 other states.

The Group also owns a wind turbine manufacturing plant in Iowa and a Nevada Solar One, a 64 MW CSP plant in Nevada, and has plans to develop additional solar projects in states across the Southwest.

Fort Irwin: A 23,000−strong military and space complex

Fort Irwin is a large U.S. military complex located in the Mojave Desert, halfway between Los Angeles (245 km to the southwest) and Las Vegas (290 km to the northeast).

The base sprawls over 4,000 square meters and is home to the U.S. Army’s largest training camp (5,000 recruits from all over the country arrive there every month) and NASA’s Goldstone Deep Space Communications Complex, commonly called the Goldstone Observatory, whose colossal antennas are used for space mission communications. The most important antenna has a diameter of 70 meters and is able to establish and maintain contact with the most far-flung man-made object to date: the Voyager Mars Program probe, 16,000 kilometers away from Earth.

These features make Fort Irwin a town of 23,000 inhabitants made up of military personnel and civilians and their respective families. The base has hangars and barracks, but also residential housing, elementary and high schools, health centers, movie theatres, museums, churches, restaurants and many of the other amenities usually available in large communities.

Corporate information

ACCIONA is one of Spain’s leading business corporations. The Company operates in infrastructure, energy, water treatment and services in more than thirty countries. Its corporate motto, “Pioneers in Sustainable Development,” reflects the Company’s commitment to contributing to economic growth, social progress and environmental balance. ACCIONA is sector leader in the Dow Jones Sustainability Index, and posted revenues of €12.67 billion in 2008. The Company has a workforce of 35,000 and is quoted on the IBEX 35 blue chip index (ANA.MC).

ACCIONA Solar Power is revolutionizing the development, construction, and operation of concentrating solar power (CSP) plants. ACCIONA Solar Power is a majority-owned affiliate of ACCIONA Energy North America Corporation, a wholly-owned subsidiary of ACCIONA Energy, a division of the international company ACCIONA SA, headquartered in Madrid, Spain. In 2005, ACCIONA Energy purchased a 55 percent stake in Solargenix and the joint venture became ACCIONA Solar Power in 2006. It designs, develops and operates large-scale concentrating solar power plants, including the largest concentrating solar power plant to be completed in the world since 1991, Nevada Solar One (64 MW) in Boulder City, Nevada. For more information, visit www.acciona.com.

ACCIONA Energy is a leading player in the field of renewable energies. It has installed more than 8,400 MW of different technologies – wind power, hydroelectric, solar and biomass – for itself or for clients. In solar power, ACCIONA Energy has installed in Nevada (US) the largest CSP plant built anywhere in the world in the last eighteen years. The Company recently completed construction of its first plant in Spain and has several facilities at varying stages of construction and development. With regard to solar photovoltaic power, ACCIONA Energy has installed 115 MWp, including a 46 MW plant, the largest of its kind in the world, located in Portugal. The Company also manufactures wind turbines produced with in-house technology, as well as producing biodiesel and bioethanol. ACCIONA Energy delivers services to clients interested in renewables projects.

Clark Energy Group LLC provides full-service energy solutions for public and private sector organizations with a focus on energy efficiency and renewable energy development. Clark was recently awarded a $5 billion Super Energy Savings Performance Contract (ESPC) by the Department of Energy. Clark Energy Group is affiliated with Clark Realty Capital and the Clark Construction Group. For more information, visit www.clarkenergygroup.com.

]]>California utilities will be required to purchase power from these small-scale producers at set rates, that could be between 15 and 17 cents kwh, a level that some companies believe won't generate much investment in new solar, according to the report.

A separate feed-in tariff is currently under consideration by the California Public Utilities Commission (CPUC). That program would require the state's three publicly owned utilities to purchase power from solar power systems between 1 MW and 20 MW in size. Developers of these systems would compete in reverse auctions to set the purchase price, and the entire program would be capped at 1,000MW of solar capacity.

Schwarzenegger reportedly sent a letter to the State Senate stating that the CPUC should proceed with its program, because the state will need "all of the tools available" to meet its renewable energy goals.

The Sacramento Municipal Utility District (SMUD) in July established its own feed-in tariff, and Ben Block of the World Watch Institute wrote in August that North America is at the tipping point in recognizing the effectiveness of these programs for incentivizing renewable energy development.

]]>

Dow Chemical Solar shingles that any roofer can install.

Dow Chemical has unveiled a residential roof shingle in the form of a solar panel designed to be integrated into asphalt-tiled roofs.

Jane Palmieri, managing director of Dow’s Solar Solutions unit, said the Powerhouse thin-film shingle slashes installation costs because it can be installed by a roofer who is already building or retrofitting a roof.

“As a roofer is nailing asphalt shingle on roof, wherever the array needs to be installed he just switches to solar shingle,” said Ms. Palmieri, who said the solar singles are similarly attached to the roof with nails.

“You don’t have to have a solar installation crew do the work or have an electrician on site,” she added. “The solar shingle can be handled like any other shingle – it can be palletized, dropped from a roof, walked on.”

An electrician is still needed to connect the completed array to an inverter and to a home’s electrical system, but unlike conventional solar panels that must be wired together, the solar shingles plug into each other to form the array.

Dow plans to begin test-marketing the solar shingle in mid-2010, initially targeting new-home construction. Ms. Palmieri said the market could be worth $5 billion by 2015 and noted that 90 percent of homes in the United States use asphalt shingles.

Dow designed the shingles, which will initially be manufactured at the company’s Midland, Mich., facility. Global Solar of Tucson, Ariz., is supplying the thin-film solar cells.

Thin-film has generally not been used for residential systems because of its relatively low efficiency – Global Solar’s cells are 10 percent efficient. That means a larger array is required generate the same of amount of electricity as conventional solar panels.

But Dave Parrillo, the senior research and development director for Dow Solar Solutions, said the solar shingles can offset between 40 percent and 80 percent of a home’s electricity consumption.

Ms. Palmieri said a solar shingle array is 10 percent to 15 percent cheaper than a standard rack-mounted solar panel system and about 40 percent less expensive than competing building-integrated photovoltaic products.

“Our objective is to prove that this can be a mainstream adopted product,” she said.

]]>Sierra Solar I is a subsidiary of GA-SNC Solar LLC - a collaboration between Sierra Nevada Corporation and Gestamp Asetym Solar North America, Inc. Construction is expected to commence in November 2009 with all three sites operational by June 2010. (Source: Sys Con Media, September 28, 2009)

Contact: Eren Ozman, President, Sierra Nevada Corporation, (775) 331-0222, www.sncorp.com; GA-Solar, www.ga-solar.com]]>

Contact: Bob Forcier, CEO, Rose Street Labs Energy, (602) 431-6020, [email protected], www.rslenergy.com]]>

Contact: Robert Butcher, President and CEO, Sustainable Energy Technologies, (403) 508-7177 ext 111, www.sustainableenergy.com]]>

Contact: Peter Dalpe, Honeywell Electronic Materials, (973) 455-4908, [email protected], www51.honeywell.com/sm/em]]>

Contact: Michael Russak, EVP, Business Development, Intevac, (408) 986-9888, www.intevac.com; Tom Djokovich, CEO, Xsunx, (888) 797-4527, www.xsunx.com]]>

Contact: Jack Hidary, Chairman, Global Solar Center, (212) 790-2872, [email protected], www.globalsolar.com.]]>